When joining 2x4's at a 90* angle, how does the strength of a pocket hole joint (end grain of one board connecting to face grain of another board) compare to that of a mitered joint (both boards cut to 45* and joined)?

Seems both joints have screws driven in at an angle to the grain - not parallel to the grain (weakest), and not perpendicular (strongest), but somewhere in between. Are they fairly similar from a strength perspective? Any reason to choose one or the other if you have the tools to make both? Miter joint has the advantage of looking better as it has no exposed end grain. And without a miter saw, pocket hole joint has the advantage of being easier to make. Any other advantages for either joint?

Views: 4829

Replies to This Discussion

-

Joe,

I do them both ways.

When joints are exposed, I use the "miter" joint---

it looks neater.

Place the pocket holes and screws on the far side.

-

I may be misinterpreting this, but if you use a miter joint, and place the pocket holes on the inside (to conceal them), then the screws are angling away from the face of the piece being attached, and that face is angling away from the screws, so it seems like you'd get too little screw running into the second piece.

If you placing the pocket holes on the outside, then the above isn't an issue, but having pocket holes on the outside seems to somewhat defeat the purpose of using miter joints in the first place. Though I suppose the pocket holes can be covered up. Is that the purpose of using pocket holes for miter joints? I.e., you can more easily cover up the pocket holes than screws that are flush with the wood?

-

Joe,

I am curious as to which type of miter you are referring to. Is it going to be like a picture frame or more like a drawer box? If it is going to be like a drawer box, pocket holes unfortunately will not work since there will not be enough material for the screw to hold on to without going through the other side. If it is like a picture frame, pocket holes will work. However, the pocket holes will be relatively close to the edge of your material. The difference in strength would be minimal when comparing these two methods. It is more dependent on the look that you are going for in your final piece. If you have any other questions please let us know.

-

I was thinking of the 45* miters you often see on workbench aprons. The pocket hole alternative is to skip the miter cuts and join end grain of one board to face grain of another board. Seems that the relation of the screws to the grain isn't so different between these two types of joints, but I could be completely wrong!

-

Joe,

Strength-wise you will not see much of a difference, especially with this application. It would be more of which one you think looks better. I will warn you that you will need to make sure that your corners match up pretty close or it will cause more issues.

-

Thanks for your response.

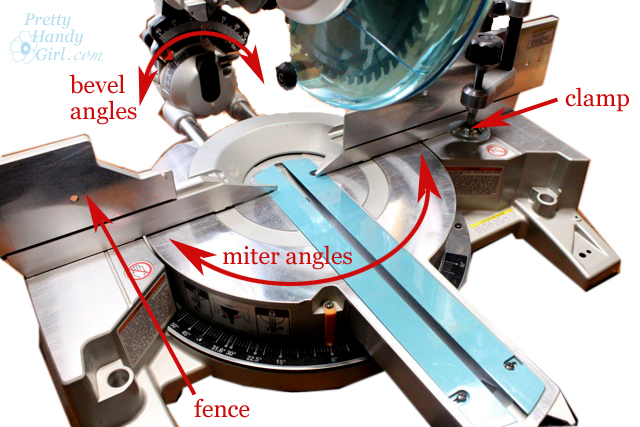

I was thinking that I should have referred to the cut I'm describing as a bevel cut rather than a miter cut since I would make it with the bevel adjustment of a miter saw. But then it occurred to me that if I rotate the workpiece, the bevel cut just became a miter cut. Of course since the cut I'm describing is along the wider face of the workpiece (e.g., 2x4 or 2x6), one wouldn't make this cut with the miter adjustment of the saw because it would require a much less stable position for the workpiece than a bevel adjustment, as the latter allows the work to be laid on its wider side.

-

MITER: Used to make a picture frame, door frame, etc.

BEVEL: Used to make a simple box without end grain showing (e.g. without butt joints)

-

Removing mechanical fasteners from the equation, e.g. screws of any type, then you are comparing the strength of two joints: (1) a "butt" joint, where the end grain of one board is joined to the face grain of the other board, and (2) a "miter" joint where the end grain of each board is cut to complimentary 45-degree angles, then joined together. In such an apples-to-apples comparison, the butt joint is stronger because in involves some long grain of the wood. A miter joint is one of the weakest joints in woodworking because it is end-grain to end-grain. That is why miters are always reinforced with something, e.g. a half-lapped miter, a biscuit, dowels, splines, dovetail keys, etc.

If you are talking about reinforcing both joints with pocket screws, I think the butt joint is going to again be stronger. This is likely to cause some controversy so let me say it again to make sure we're all on the same page: A joint fastened with pocket holes is still likely to be stronger if the screw is being sunk into long grain than a joint in which the screw is being sunk into end grain. In the butt joint scenario, the screw is being driven through the end grain of the board with the pocket drilled out, into the long grain of the mating piece. The mitered joint has screws driven through the end grain of the board with the pockets, into the end grain of the mating piece. I posit that it is much easier to forcibly remove a screw driven into the end grain of wood than it is to remove one driven into face grain.

But to echo KregCS, beware venturing into 360-degrees worth of miter joints. If you aren't set up to cut perfect 45-degree angles, you're going to have gaps in your joints. All of your workpieces must be EXACTLY the same length and your joints have to be precisely cut. If your cut is off by 0.5 degrees, then you will wind up with 2-degrees of gap around your apron because the error is compounded across the four joints.

Good luck!

-

Russ, thanks for that very informative post!

© 2024 Created by KregRep.

Powered by

![]()

Badges | Report an Issue | Privacy Policy | Terms of Service