I'm building plywood shelving. What recommendations would you have for the edges? Spackle vs edge banding? Also, any recommendations of finishing with paint, shellac, vs a varnish? I'm a newbie at this. Used my rip cut and was very pleased by the outcome. Moving on to using my R3 jig in a bit, but I'm debating whether to apply surface finishing before joining the pieces. Enjoying this new hobby a lot.

Views: 6399

Replies to This Discussion

-

I personally would edge banding or real wood on the edge.

Edge banding is easy, buy some banding that matches your wood and use an old (or cheap) iron to put it on, then carefully roll it smooth with a roller or a dowel. You will also need to trim the excess off the side with a sharp knife or razor. Done carefully, the results are very impressive. Don't use your clothes iron unless you want permanent wood glue on your clothes. I found an iron at Walmart that was cheaper than a used one from Goodwill.

You can also use real wood along the edge, too, but to make that look really nice and hold up, you will need to do more that just glue some strips of wood along the edge. You will need a router and some Edge Banding Router Bits (follow the link to see what I'm talking about). This will hold up longer that simple edge banding, however, it may be a bit much for a beginner, especially if you have limited access to the necessary tools.

-

Thank you very much. Will look into the edge banding as the router is currently not an option.

Any recommendations on brands or manufacturer of edge banding?

James P. Cottingham said:I personally would edge banding or real wood on the edge.

Edge banding is easy, buy some banding that matches your wood and use an old (or cheap) iron to put it on, then carefully roll it smooth with a roller or a dowel. You will also need to trim the excess off the side with a sharp knife or razor. Done carefully, the results are very impressive. Don't use your clothes iron unless you want permanent wood glue on your clothes. I found an iron at Walmart that was cheaper than a used one from Goodwill.

You can also use real wood along the edge, too, but to make that look really nice and hold up, you will need to do more that just glue some strips of wood along the edge. You will need a router and some Edge Banding Router Bits (follow the link to see what I'm talking about). This will hold up longer that simple edge banding, however, it may be a bit much for a beginner, especially if you have limited access to the necessary tools.

-

I don't have a preference as to who makes the edge banding. I usually buy whatever they have in stock.

IF the plywood looks nice, I would put a finish on it. Whether you use shellac or varnish or poly is more of a preference than anything else. I personally love the look of wood and feel painting is a shame unless it's going outside. Then painting becomes (almost) as necessity.

-

Thank you very much. You've been a big help.

-

I like the edge banding that has "hot melt" glue, to bond the banding.

Easy to apply using an iron.

With hot melt glue, you can reheat the area, if you need to reseat or reposition the banding.

It can easily be trimmed using a "sharp" knife blade, followed by breaking the edge with 220 grit sandpaper.

I get my edge banding from Rockler.

-

Hi Johanne, I am not too big on using the iron on tape method as eventually they will fail. I will use a solid wood edge of about a 1/4 inch thick and will use a and plane and sandpaper to make the final sizing of the edge if I am making it the same thickness as the shelf. I attach it with glue and a micro pin.

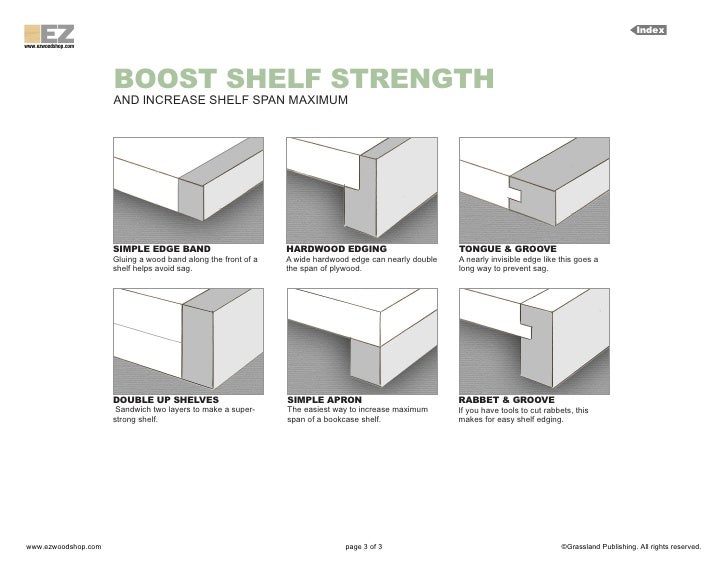

The best method is to use a thicker piece to strengthen the front of the shelf and glue and a kreg pocket screw. Even in most cabinet building projects you are doing yourself a big favor by making the shelf front thicker as eventually they will sag in the middle and this is one method of helping to prevent this. It is my desired practice to cut the edge 3/4 thick and 1& 1/4 to 1& 1/2 inch wide.

In building furniture it actually a stronger shelf but will look better in the long run. It is something that will cheapen your project if you build a nice cabinet and or piece of furniture and then make a cheap shelf and is a kin to using walnut and or other fine wood to build the case and then use a particle board product for the shelving.

While on the subject here is a trick I use when putting the bands on to the shelf. I will place a bout 2 layers of newspaper of similar thickness under the shelf part that is being banded. With the shelf on a flat solid surface you can apply pressure down on the piece and then lay the band on the surface that is not covered with paper and then attach band to the shelf. the thickness will place the upper edge of the band very near and flat to the upper surface. Finish with a hand plane and or sandpaper. It is much more accurate and easier that just trying to line it up by eye.

Another way I often band shelves is by using a router and a spline.

I have some bits that I use and on anything that is a high grade build I will spline the band to the shelf.

There s also some bits of which is made for banding shelves of which are a specialty bit and cost around 180.00 a set The consist of two separate bits and cut a "V" notch into shelf material and a matching point on the solid wood band. These are glued to he shelf and are incredible strong. They are available at Eagle America. A bit pricey for the hobby type woodworker but if you build a lot of shelving they would be worth the investment.

-

Thanks for the information. I'll check the wood depot and see what they offer.

What did you mean by: "It is my desired practice to cut the edge 3/4 thick and 1& 1/4 to 1& 1/2 inch wide."?

If possible do you have before and after pictures?

Thanks again.

Jay Boutwell said:Hi Johanne, I am not too big on using the iron on tape method as eventually they will fail. I will use a solid wood edge of about a 1/4 inch thick and will use a and plane and sandpaper to make the final sizing of the edge if I am making it the same thickness as the shelf. I attach it with glue and a micro pin.

The best method is to use a thicker piece to strengthen the front of the shelf and glue and a kreg pocket screw. Even in most cabinet building projects you are doing yourself a big favor by making the shelf front thicker as eventually they will sag in the middle and this is one method of helping to prevent this. It is my desired practice to cut the edge 3/4 thick and 1& 1/4 to 1& 1/2 inch wide.

In building furniture it actually a stronger shelf but will look better in the long run. It is something that will cheapen your project if you build a nice cabinet and or piece of furniture and then make a cheap shelf and is a kin to using walnut and or other fine wood to build the case and then use a particle board product for the shelving.

While on the subject here is a trick I use when putting the bands on to the shelf. I will place a bout 2 layers of newspaper of similar thickness under the shelf part that is being banded. With the shelf on a flat solid surface you can apply pressure down on the piece and then lay the band on the surface that is not covered with paper and then attach band to the shelf. the thickness will place the upper edge of the band very near and flat to the upper surface. Finish with a hand plane and or sandpaper. It is much more accurate and easier that just trying to line it up by eye.

Another way I often band shelves is by using a router and a spline.

I have some bits that I use and on anything that is a high grade build I will spline the band to the shelf.

There s also some bits of which is made for banding shelves of which are a specialty bit and cost around 180.00 a set The consist of two separate bits and cut a "V" notch into shelf material and a matching point on the solid wood band. These are glued to he shelf and are incredible strong. They are available at Eagle America. A bit pricey for the hobby type woodworker but if you build a lot of shelving they would be worth the investment.

-

what I am refering to is to cut a pice of solid wood of which is the the normal 3/4 inch thick and I cut it so that it is 1 &1/4 inch and sometimes at 1 &1/2 inch thick and add this to the front of the shelf. I do this

rather than to cut it so it is 3/4" thick. That way I can add it to the front of the shelf making the shelf appear thicker. This makes the front of the shelf a lot more resistant to bowing. In doing this you will need to cut the shelf 3/4 inch less that you would need it as the 3/4 inch added to it makes it too deep. With the extra thickness added to the shelf you can use the kreg pocket hole method of attaching the band.

With the tape method you are only covering the shelf edge. It is not my favorite method of just adding a 1/4 inch thick piece of wood to the front if I and do it the other way. However I will elect to use the 1/4 inch thick wood rather that use tape.Thanks for the information. I'll check the wood depot and see what they offer.

What did you mean by: "It is my desired practice to cut the edge 3/4 thick and 1& 1/4 to 1& 1/2 inch wide."?

If possible do you have before and after pictures?

Thanks again.

Jay Boutwell said:Hi Johanne, I am not too big on using the iron on tape method as eventually they will fail. I will use a solid wood edge of about a 1/4 inch thick and will use a and plane and sandpaper to make the final sizing of the edge if I am making it the same thickness as the shelf. I attach it with glue and a micro pin.

The best method is to use a thicker piece to strengthen the front of the shelf and glue and a kreg pocket screw. Even in most cabinet building projects you are doing yourself a big favor by making the shelf front thicker as eventually they will sag in the middle and this is one method of helping to prevent this. It is my desired practice to cut the edge 3/4 thick and 1& 1/4 to 1& 1/2 inch wide.

In building furniture it actually a stronger shelf but will look better in the long run. It is something that will cheapen your project if you build a nice cabinet and or piece of furniture and then make a cheap shelf and is a kin to using walnut and or other fine wood to build the case and then use a particle board product for the shelving.

While on the subject here is a trick I use when putting the bands on to the shelf. I will place a bout 2 layers of newspaper of similar thickness under the shelf part that is being banded. With the shelf on a flat solid surface you can apply pressure down on the piece and then lay the band on the surface that is not covered with paper and then attach band to the shelf. the thickness will place the upper edge of the band very near and flat to the upper surface. Finish with a hand plane and or sandpaper. It is much more accurate and easier that just trying to line it up by eye.

Another way I often band shelves is by using a router and a spline.

I have some bits that I use and on anything that is a high grade build I will spline the band to the shelf.

There s also some bits of which is made for banding shelves of which are a specialty bit and cost around 180.00 a set The consist of two separate bits and cut a "V" notch into shelf material and a matching point on the solid wood band. These are glued to he shelf and are incredible strong. They are available at Eagle America. A bit pricey for the hobby type woodworker but if you build a lot of shelving they would be worth the investment.

-

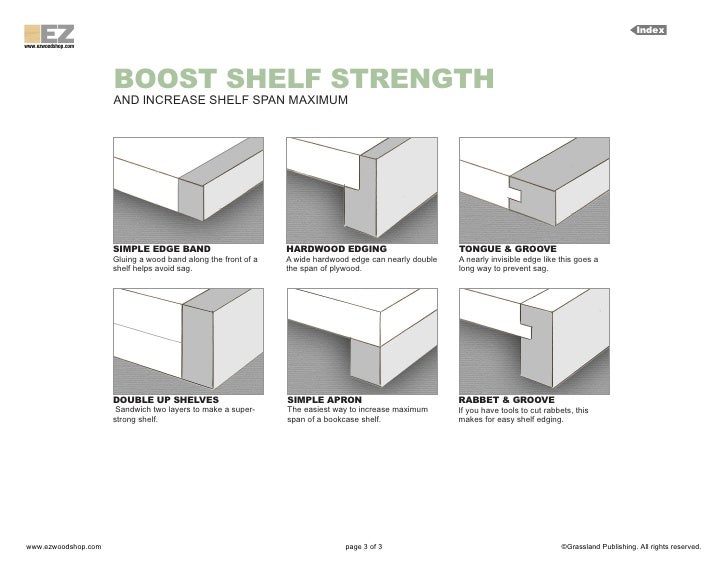

Edge covering options:

A. Router bits to make profile cuts on router table

B. Various edge banding

C. Edge shelf spline joinery

D.

E. Mitered edge

F. Edge banding at corners to cover plywood edges

-

The diagram of the bits that Ken shows in his comment depicted in figure "A" is the same bits that I mentioned in my post and are available at Eagle America. The others depictions are the methods that I was talking about in my post.

It makes it a simple process and are much better methods that using the iron on tape. Thanks Ken for finding some examples.

-

Got it; that's a great idea.

Thanks!

Jay Boutwell said:what I am refering to is to cut a pice of solid wood of which is the the normal 3/4 inch thick and I cut it so that it is 1 &1/4 inch and sometimes at 1 &1/2 inch thick and add this to the front of the shelf. I do this

rather than to cut it so it is 3/4" thick. That way I can add it to the front of the shelf making the shelf appear thicker. This makes the front of the shelf a lot more resistant to bowing. In doing this you will need to cut the shelf 3/4 inch less that you would need it as the 3/4 inch added to it makes it too deep. With the extra thickness added to the shelf you can use the kreg pocket hole method of attaching the band.

With the tape method you are only covering the shelf edge. It is not my favorite method of just adding a 1/4 inch thick piece of wood to the front if I and do it the other way. However I will elect to use the 1/4 inch thick wood rather that use tape.Thanks for the information. I'll check the wood depot and see what they offer.

What did you mean by: "It is my desired practice to cut the edge 3/4 thick and 1& 1/4 to 1& 1/2 inch wide."?

If possible do you have before and after pictures?

Thanks again.

Jay Boutwell said:Hi Johanne, I am not too big on using the iron on tape method as eventually they will fail. I will use a solid wood edge of about a 1/4 inch thick and will use a and plane and sandpaper to make the final sizing of the edge if I am making it the same thickness as the shelf. I attach it with glue and a micro pin.

The best method is to use a thicker piece to strengthen the front of the shelf and glue and a kreg pocket screw. Even in most cabinet building projects you are doing yourself a big favor by making the shelf front thicker as eventually they will sag in the middle and this is one method of helping to prevent this. It is my desired practice to cut the edge 3/4 thick and 1& 1/4 to 1& 1/2 inch wide.

In building furniture it actually a stronger shelf but will look better in the long run. It is something that will cheapen your project if you build a nice cabinet and or piece of furniture and then make a cheap shelf and is a kin to using walnut and or other fine wood to build the case and then use a particle board product for the shelving.

While on the subject here is a trick I use when putting the bands on to the shelf. I will place a bout 2 layers of newspaper of similar thickness under the shelf part that is being banded. With the shelf on a flat solid surface you can apply pressure down on the piece and then lay the band on the surface that is not covered with paper and then attach band to the shelf. the thickness will place the upper edge of the band very near and flat to the upper surface. Finish with a hand plane and or sandpaper. It is much more accurate and easier that just trying to line it up by eye.

Another way I often band shelves is by using a router and a spline.

I have some bits that I use and on anything that is a high grade build I will spline the band to the shelf.

There s also some bits of which is made for banding shelves of which are a specialty bit and cost around 180.00 a set The consist of two separate bits and cut a "V" notch into shelf material and a matching point on the solid wood band. These are glued to he shelf and are incredible strong. They are available at Eagle America. A bit pricey for the hobby type woodworker but if you build a lot of shelving they would be worth the investment.

-

Thanks Ken.

Great stuff; appreciate it. Really help me visualize the edge-banding methods.

Ken Darga said:Edge covering options:

A. Router bits to make profile cuts on router table

B. Various edge banding

C. Edge shelf spline joinery

D.

E. Mitered edge

F. Edge banding at corners to cover plywood edges

© 2025 Created by KregRep.

Powered by

![]()

Badges | Report an Issue | Privacy Policy | Terms of Service