Here is an interesting video. http://lumberjocks.com/Stevinmarin/blog/34799

Anyone built a french cleat system and has pictures to share.

Views: 16686

Replies to This Discussion

-

Please please post pictures.

-

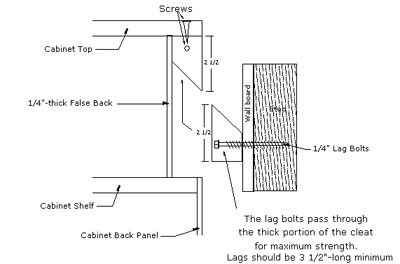

I do not have photos but a cleat method that I have used several times before to make a simple method of hanging wall cabinets. I use two pieces of 3/4" ply wood with a 45 degree angle cut on the edges. The cleat is the length of the cabinet run with one piece attached to the wall studs with the toe of the miter outward from the wall and facing up. The second piece is attached to the cabinet box also with the toe of the miter also on the outward side away from the cabinet back and facing downward. (toe of miter is the long point). The cabinet is then hung over the miters and the weight will keep it in place but should have at least one two screws driven through the back of the cabinet into the cleats. If using 3/4" which is the minimum I would use you will need to add a 3/4" strip on the cabinet back at the bottom to close the space behind the cabinet. Drive in some screws through the cabinet back and the strip and into a couple studs to prevent the cabinet bottom from being pulled away from the wall.

The easiest method to make the cleat is to rip a piece of 3/4" ply about 4 inches wide and then rip a 45 degree miter down the middle and then attach to wall and cabinet as descrived above. The only issue with this is that you extend the cabinet out 3/4" from the wall and at the end of a cabinet run where it is exposed to eye, you will need to add 3/4" to the cabinet end. I build raised panels for the ends and just build the 3/4" wider that the cabinet end and if the wall is bowed I will add some additional and scribe cut the end to hide the wall defects.

One good advantage to using the French cleat system is the you can shim out bows and wall defects by using shims between the cleat and the wall studs and have a easy installation of a upper run of cabinets. It is considerable easier to attach all of the cabinets for a wall together while on the floor than it is to attach a cabinet at a time onto a wall .

There are commercial cleat systms available made of metal that are not as thick as the 3/4" ply and be used as an option, but my preference is to make my own.

This is also great for the person whom likes to move cabinets around in a shop as it makes it quick and simple.

-

Steve Ramsey of Woodworking for Mere Mortals did a great video on french cleats recently.

-

Steve's video is what started me on this quest. Thanks everyone for your help.

-

Hi Gary,

Here are a variety of photos/images, of French Cleats in use.

The French Cleat, concept has been around for many years.

Where did it originate?

Don't know for sure---nothing archived in history.

However, in the early 17th century, houses build in France, were mainly constructed of earthen materials.

The walls were not strong enough to hang heavy wooden objects;

therefore, cleats, a simple object, were fashioned from wood and affixed to the walls, to hang heavy wooded objects.

I recall seeing my granddad, having his horses harness, neck collar, and the like, hanging on cleated wood pegs. The peg was affixed to a block, that hooked on the cleat---and adjustable from side to side,

so as to accommodate various size objects.

He also had many of such fashioned items in his workshop and other buildings.

A peg into a block, was a commonly used item.

In many instances, it was more useful over putting a spike, nail or peg on a wall or in a post.

Put pegs, or the like, in a block and hang up your yard or garden tools.

(Attach 1x stock on a wall, with the 45 degree chamfer on the back side, and hang the cleated block).

© 2024 Created by KregRep.

Powered by

![]()

Badges | Report an Issue | Privacy Policy | Terms of Service