Make your own shop-made clamping & assembly workbench.

........

........

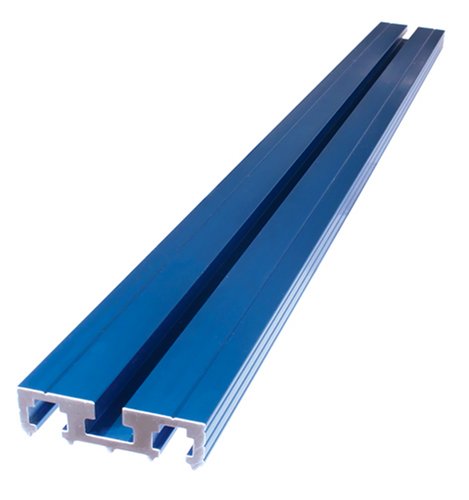

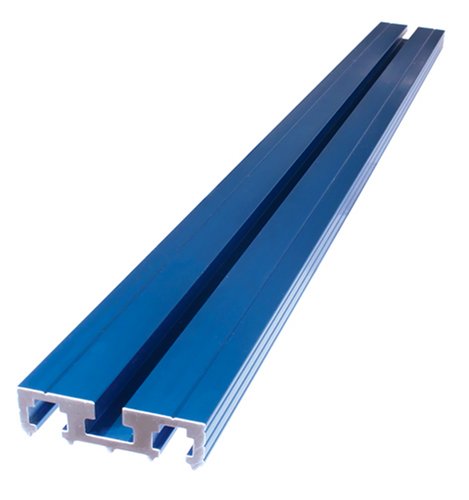

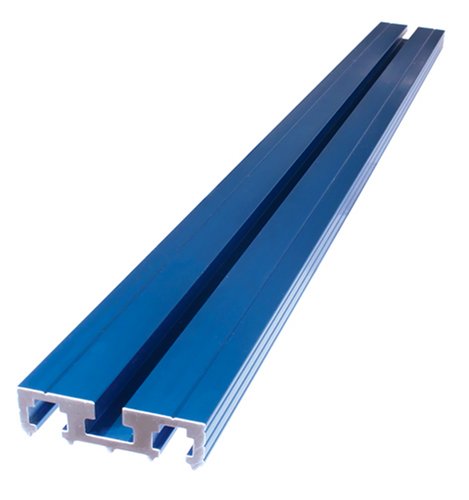

Kreg Klamp Track

locate several of these units, banked side-by-side, to the desired depth of your top.

Make a work-top base from 3/4" MDF, or the like, to a width and depth, as applicable.

Fasten the tracks to the base.

Secure the assembled components to work-stand.

This concept will permit nearly limitless clamping opportunities.

Views: 2771

Replies to This Discussion

-

What is the best width and length for furniture like dressers, night stands & beds?

-

A 4ft by 3ft table size will suffice nicely, for most uses.

-

Thank you for your advice. Kevin

-

Klamp trak Worktop Option(s):

NOTE: each Klamp Trak is 33-3/4" long x 2-1/4" wide x 11/16" thick.

OPTION(S):

A) Make a sub-base 33-3/4" long, the same length as the Klamp Trak.

For a base depth of 22.50", 10 tracks are needed, when banked side-by-side.

B) For a base depth of 47.25", 21 tracks are needed, when banked side-by-side.

C) install 11/16" thick spacers, "X" inches wide---and locate between each track.

Installing spacers between traks, will reduce the quantity of traks needed for a worktop.

D) Two tracks, at 90 degrees to each other. One located along one edge of the sub-base, and another at 90 degrees. Sub-base of 36" x 36".

Diagram "A"

1) three traks---sub-base of 36" x 38-1/4"

2) four such traks---sub-base of 38-1/4 x 38-1/4.

E) Multiple traks for a larger worktop

Diagram "B"

Note:

There are nearly limitless design possibilities.

The Traks can be butted, end-to-end, or cut to a desired length, to suit.

Suggest draw-out the design options you'd like, and/or make a scale model, so as to give a visual of the desired worktop.

-

Can T Tracks be used in this set up and be accurate. I own peachtree types for miter gages and they attach with wood screws. What type of clamping system is acceptable also for precision type work?

-

Kevin,

"T-tracks" are generally made of thinner material---

held by small screws---

suitable for light duty clamping pressures.

T-tracks can permanently deform when exposed to heavy clamping pressures.

The Kreg Klamp Trak, is intended to be secured to the sub-base with bolts and nuts, on 2" centers,

which will provide for heavy pressure clamping.

Simple "C", "F", "pipe" or "bar" clamps can be used for clamping.

It's how these type clamps are used that will provide the desired end result.

For clamping larger pieces, a pipe or bar clamp may be needed.

"F" clamps for small to med size pieces, with light to med clamping pressures.

"C" clamps are available in a variety of sizes.

For light clamping to heavy clamping pressures.

"Web" or belt type clamps are also available, and suitable for clamping square, rectangular and round type structures.

For many applications, auxiliary devices may be needed,

such as a "pad" under a clamp face to prevent marring or distortion of the work-piece surface.

"Precision type work" can be accomplished with suitable skills and tools for the end product result.

-

Thank you for you advice. Kevin

-

Hi everyone, new to the community and have a few questions and this happens to be one of them. We plan on building our own kitchen cabinets and I was a bit confused on building a clamping table, like what I need and deciding how big I need it to be.

I think the confusion for me is how many tracks I would need and why the need for 10 tracks side by side? I am confused, sorry.

I have a project we are working on now and will post the questions I have about it on another thread but I am eager to learn about Kreg and all the many uses of it.

-

I would use 2 tracks, forming a 90 degree angle. Doing it yourself might be fun, but for the money, you cant beat one that's ready to go. https://www.kregtool.com/store/c30/klamp-tablestrade/p68/klamp-tabl...

-

Hi Suzy, I have been building cabinets professionally for about 27 years now and have never used a clamping table other than a sturdy and sound 4 ft wide by 8 ft long work bench. I have build many large cabinets as big as 5 wide x 3 feet deep by 8 feet tall and found the bench more that enough to build rapidly and accurate cabinet boxes. The bench must be level and this helps keep the cabinet panels flat and square. Anything I needed to clamp I used jigs of which I clamped to this bench

A clamping table would be something that I might use when building face frames and such where there are many pieces to attach together. What I did for this is to have a grid of 2 x4 on edge which picked up the face frame pieces to enable a clamping of a face frame clamp.

I have considered a face frame clamping table made by Kreg Tools and think it is a good system but I do not have the room for something like this. For any glue up panels I use standard clamps laying flat on the bench top. The flat bench top will keep the panels flat. I normally use wax paper under the joints and on some occasions I will use newspaper and when the glue dries I scrape it off with a scrapper along with any glue. Any questions I will be happen answer them. Also welcome to the community.

-

Thank you both, Thomas and Jay. I appreciate your responses to my question.

OK, so how do I attach the rails? Directly on top of the plywood base? I am thinking of making it about 3'x4' sized.

Jay, it sounds like you make some real nice cabinets. I can only hope our projects turn out well

Thanks again.

-

Suzy, If you are going to build a small table for clamping I would inset the "T" Track Rails into the plywood so that the top of the rails is flush with the surface of the plywood. This would give you a flat surface in which you can easily move your project about on the table and position them for clamping.

It is easier to use a router and bit guided by a fence than it is a table saw but either can be used. Use a dado blade in the table saw or a dado cutting router bit in a router and take several shallow passes with the router until you have cut the dado to the correct depth.

If you take your time with the cabinet building I am sure they will turn out great.

Suzy said:Thank you both, Thomas and Jay. I appreciate your responses to my question.

OK, so how do I attach the rails? Directly on top of the plywood base? I am thinking of making it about 3'x4' sized.

Jay, it sounds like you make some real nice cabinets. I can only hope our projects turn out well

Thanks again.

© 2024 Created by KregRep.

Powered by

![]()

Badges | Report an Issue | Privacy Policy | Terms of Service